Wrecklyss

Custom Speaker Cabinet Builder

So i'm heading to Afghanistan in the near future, but got approval from my leadership to bring 2 guitars. I went yesterday and picked up my Ibanez AEL207, and will be bringing my Alvarez Jumbo as well. The obvious problem is how to protect two acoustics traveling half way around the world without creating a lot of extra weight to ship. While looking into cases, Road Runner mentioned something about a line of cases they build that gave me an idea.

Road Runner offers a line of medium duty cases made from molded foam and covered in Cordura. I don't have the resources to mold foam, but my local Lowes Hardware sells 4'x8' sheets of insulation foam that can easily be shaped with standard power tools. Several layers of it sandwiched together would be quite strong and weigh very little. A 1/4" plywood outer shell would add even more protection without adding much weight.

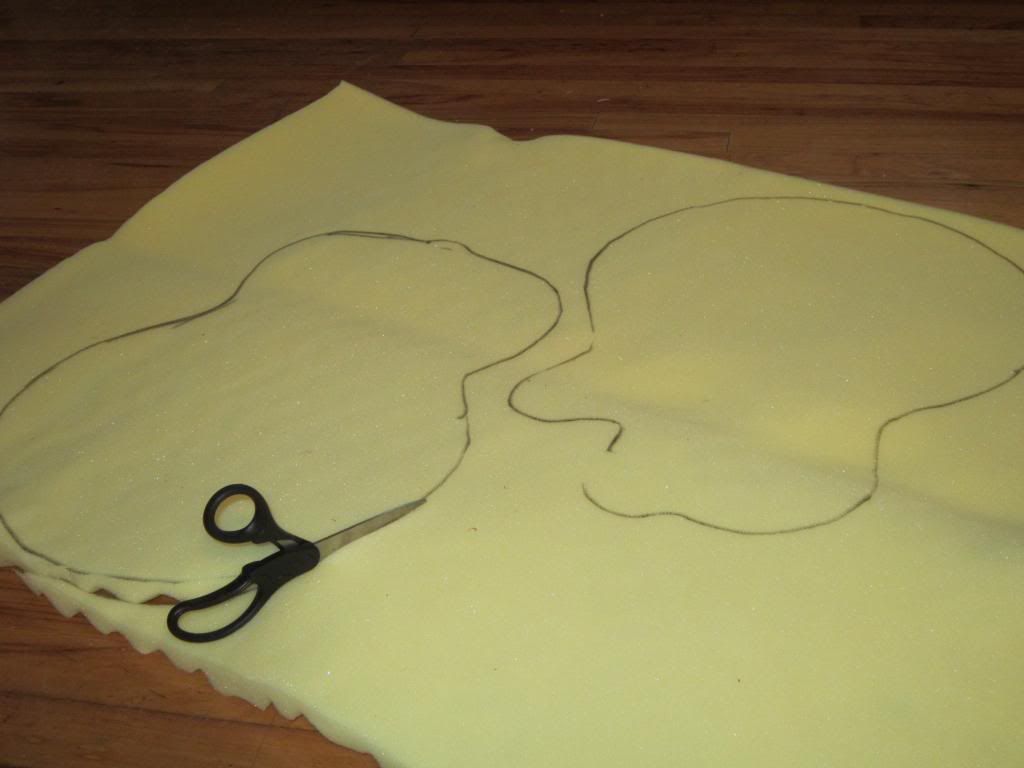

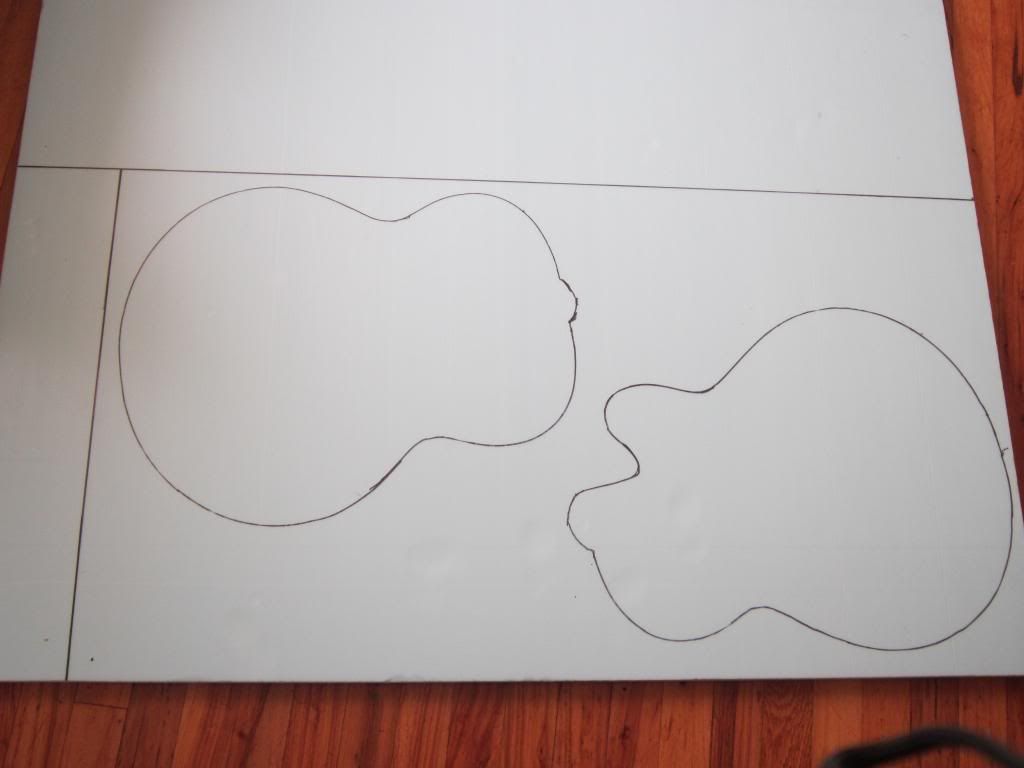

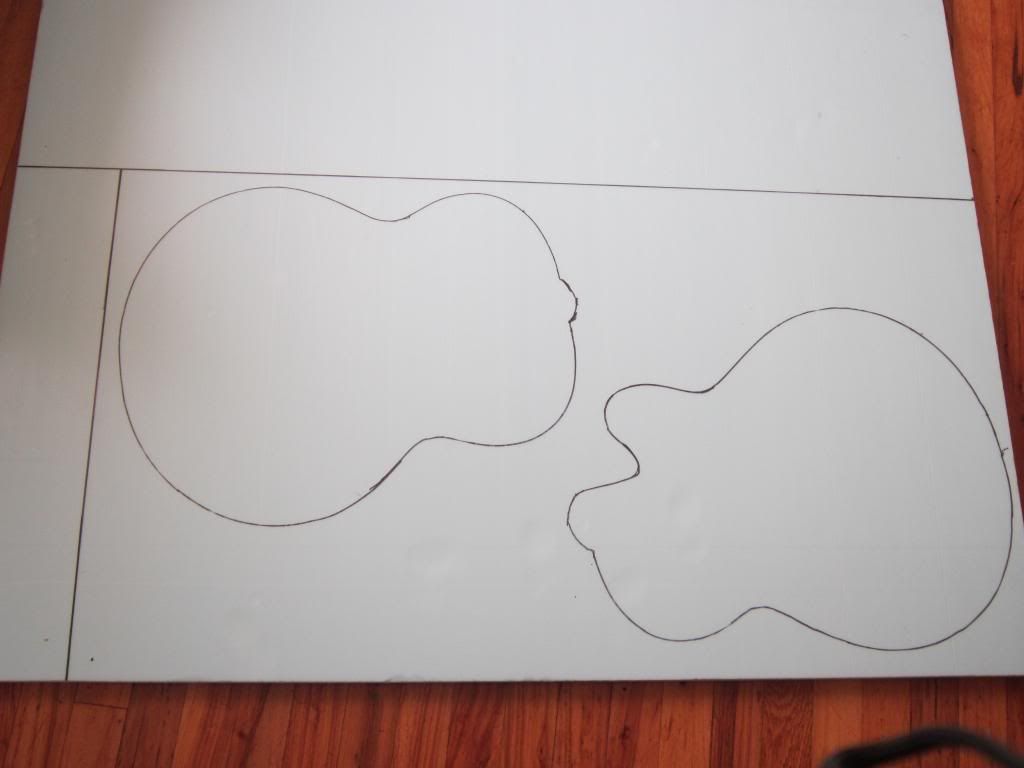

I lay both guitars in such a way they take up the least amount of room i'm comfortable with, and trace the outline of the bodies with a sharpie. I kept the Sharpie itself flat against the body, making the final outline about 3/8" wider than the guitar body itself. This will allow for lining the finished product with a soft material for scratch protection. The foam insulation board is 1" thick, so 5 layers will be sandwiched together using 3M super 90 contact adhesive.

The next 2 layers need headstock pockets cut out, and the final two need neck channels cut as well. This is what i got done yesterday before i ran out of daylight:

One more layer of foam, then i will glue the sandwich layers together and even out the cuts. I find that the foam tends to distort as you cut shapes out of the middle, so they don't all line up perfectly, but it will be easy to even them out once they are glued together.

Next will be to start building the outer case from 1/4" plywood and line the inside. I have some jungle camo tolex to cover the case in, so i will have a pretty nice finnished product. More pics to come.

Road Runner offers a line of medium duty cases made from molded foam and covered in Cordura. I don't have the resources to mold foam, but my local Lowes Hardware sells 4'x8' sheets of insulation foam that can easily be shaped with standard power tools. Several layers of it sandwiched together would be quite strong and weigh very little. A 1/4" plywood outer shell would add even more protection without adding much weight.

I lay both guitars in such a way they take up the least amount of room i'm comfortable with, and trace the outline of the bodies with a sharpie. I kept the Sharpie itself flat against the body, making the final outline about 3/8" wider than the guitar body itself. This will allow for lining the finished product with a soft material for scratch protection. The foam insulation board is 1" thick, so 5 layers will be sandwiched together using 3M super 90 contact adhesive.

The next 2 layers need headstock pockets cut out, and the final two need neck channels cut as well. This is what i got done yesterday before i ran out of daylight:

One more layer of foam, then i will glue the sandwich layers together and even out the cuts. I find that the foam tends to distort as you cut shapes out of the middle, so they don't all line up perfectly, but it will be easy to even them out once they are glued together.

Next will be to start building the outer case from 1/4" plywood and line the inside. I have some jungle camo tolex to cover the case in, so i will have a pretty nice finnished product. More pics to come.

love that stuff!

love that stuff!