Deegatron

Well-Known Member

Heya Guy's,

My first post on Sevenstring.org. 3rd Build. long time lurker... figured this build was metal enough to justify starting a thread here.

Specs:

25.5"-24.75" multiscale

Magnet cavity covers

SS jumbo frets

1-5/8" nut width

custom birdseye maple / aluminum bridge with graphtech saddles.

Tung oil finish

Padouk neck

Birdseye maple fretboard - black MOP dots... if I can find someone that'll ship em acroos the border...

Basswood body - dyed black

Curly red western cedar drop top - got a SCREAMING deal on ebay. couldn't say no...

Pickup - undecided... I've got an old beat up pickup out of an old aria pro that i'll be using for mockup.... im leaning towards a crunch lab in the bridge and no neck pickup.

Volume / tone / switch for coil split

Superstrat ish body style...

Bolt on style neck. I used six 6 mm bolts with inserts on my last build and will likely do so on this build. they make normal screws look like play toys... and im all about over doing it... im a little worried they'll pull right thru the basswood so I've got a plan to hide some maple in there....

3x3 headstock

I'll admit im a terribly slow builder but im already a ways in and i'll post updates as soon as they happen.

currently the body and drop top are jointed and glued. Just finished building a thicknessing jig for the router so I can clean up the basswood and get it down to about 1.5" thick.

See below for pictures of current progress....

That's the top with some mineral spirits on it. should pop like mad once it's finished.

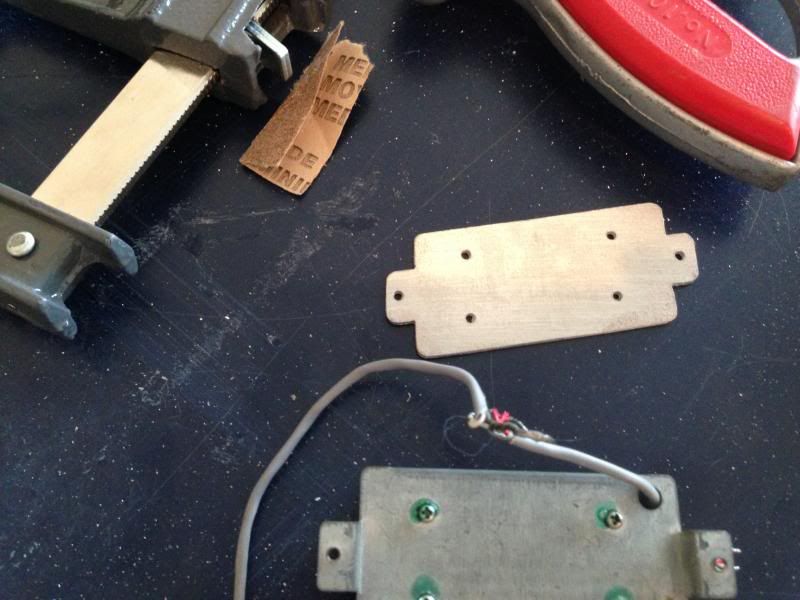

Angled pickup baseplate...

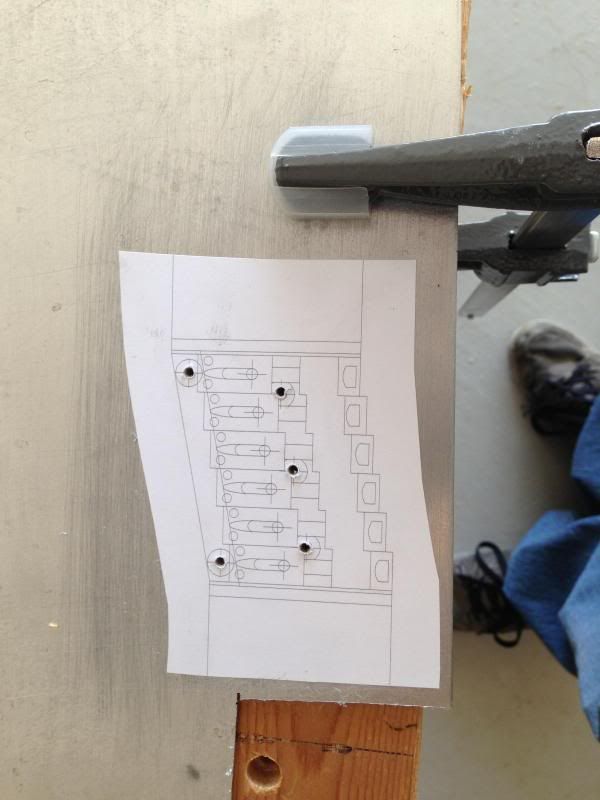

both the pickup baseplate and bridge plate were drawn in CAD printed, glued to the aluminum, drilled by hand, cut out with a hack saw and filed to the lines. took some time but actually came out nice...

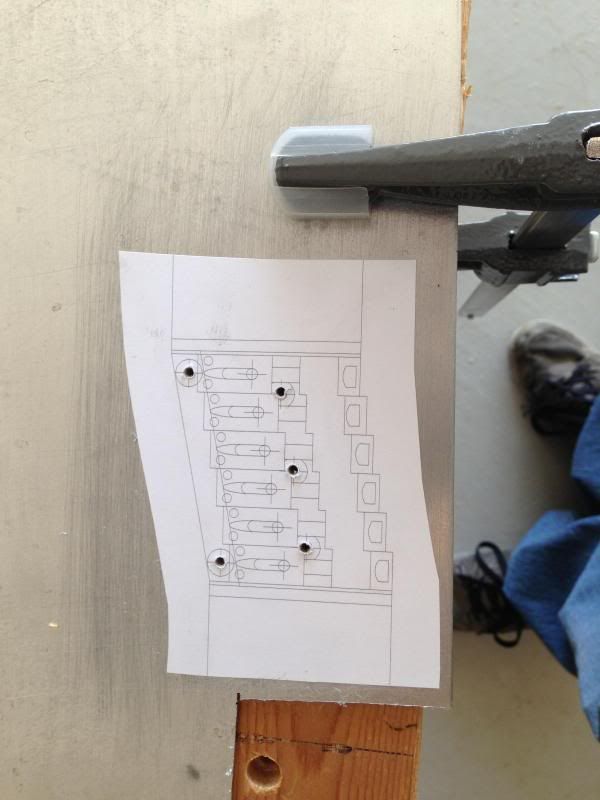

This is the bridge in process

Nearly done, just needs the maple back to hold the screws... Im waiting on a drill press before I finish this but I cant seem to find a nice one on kijiji... don't really wanna pay full price for a new one...

My first post on Sevenstring.org. 3rd Build. long time lurker... figured this build was metal enough to justify starting a thread here.

Specs:

25.5"-24.75" multiscale

Magnet cavity covers

SS jumbo frets

1-5/8" nut width

custom birdseye maple / aluminum bridge with graphtech saddles.

Tung oil finish

Padouk neck

Birdseye maple fretboard - black MOP dots... if I can find someone that'll ship em acroos the border...

Basswood body - dyed black

Curly red western cedar drop top - got a SCREAMING deal on ebay. couldn't say no...

Pickup - undecided... I've got an old beat up pickup out of an old aria pro that i'll be using for mockup.... im leaning towards a crunch lab in the bridge and no neck pickup.

Volume / tone / switch for coil split

Superstrat ish body style...

Bolt on style neck. I used six 6 mm bolts with inserts on my last build and will likely do so on this build. they make normal screws look like play toys... and im all about over doing it... im a little worried they'll pull right thru the basswood so I've got a plan to hide some maple in there....

3x3 headstock

I'll admit im a terribly slow builder but im already a ways in and i'll post updates as soon as they happen.

currently the body and drop top are jointed and glued. Just finished building a thicknessing jig for the router so I can clean up the basswood and get it down to about 1.5" thick.

See below for pictures of current progress....

That's the top with some mineral spirits on it. should pop like mad once it's finished.

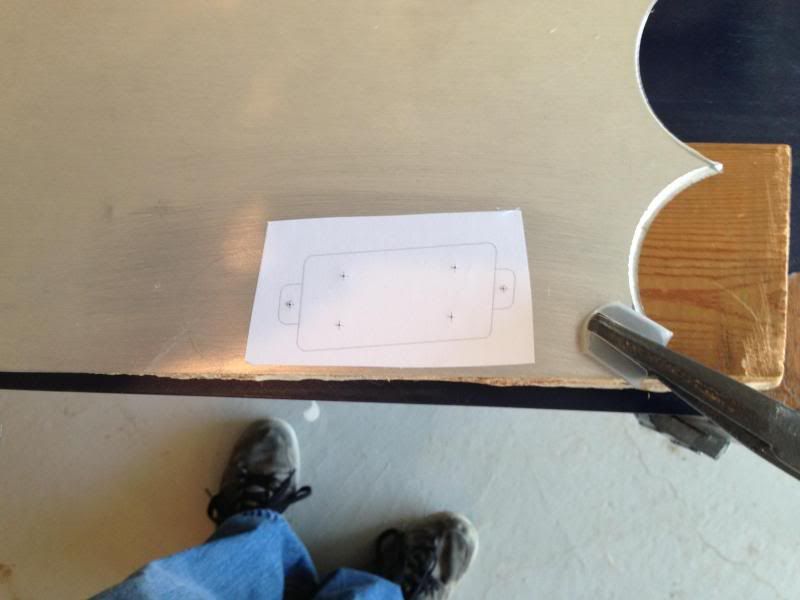

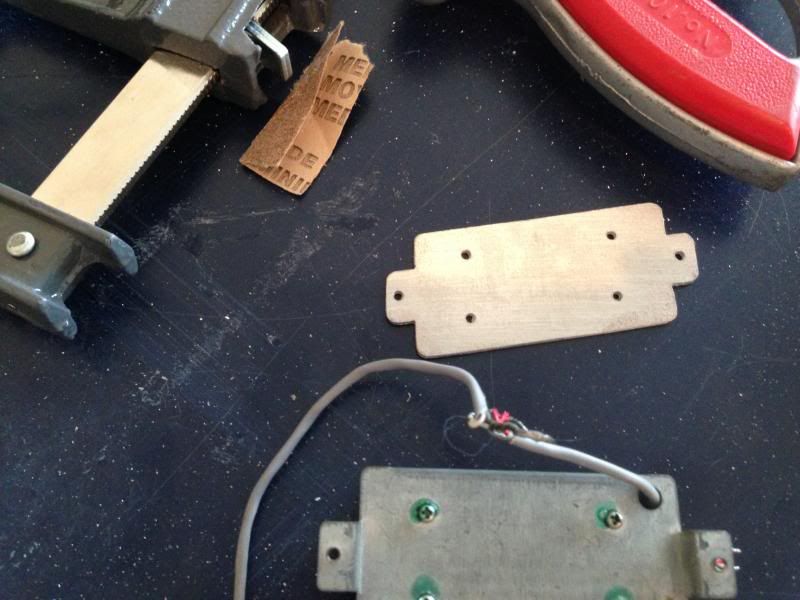

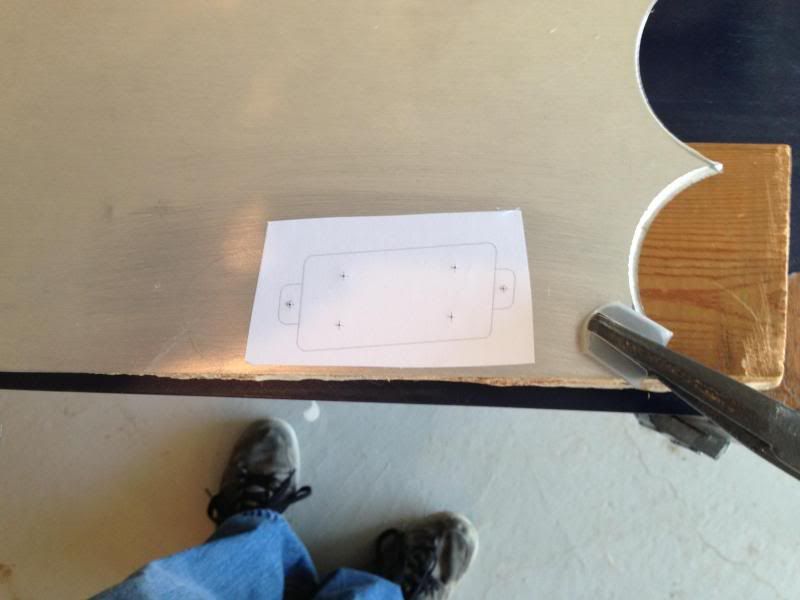

Angled pickup baseplate...

both the pickup baseplate and bridge plate were drawn in CAD printed, glued to the aluminum, drilled by hand, cut out with a hack saw and filed to the lines. took some time but actually came out nice...

This is the bridge in process

Nearly done, just needs the maple back to hold the screws... Im waiting on a drill press before I finish this but I cant seem to find a nice one on kijiji... don't really wanna pay full price for a new one...

feeling like a total douche right now.... how in gods name did i manage this?!?!?!?!

feeling like a total douche right now.... how in gods name did i manage this?!?!?!?!