Pikka Bird

Vaya Con Cornholio

^Matching headstocks are all the rage, don't be sad that fate forced you to go that route.

This site may earn a commission from merchant links like Ebay, Amazon, and others.

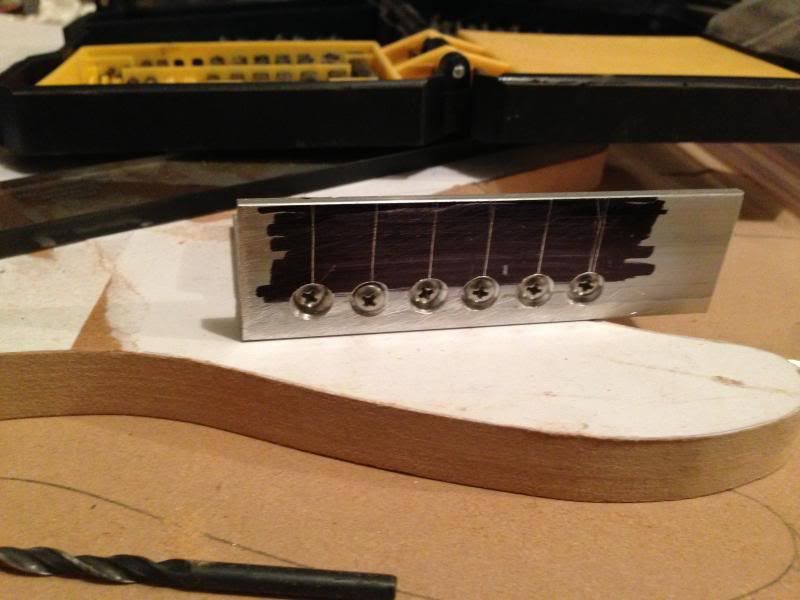

while routing the first pass on the truss rod the danm bit slipped in the chuck... I didn't notice... I would up routing some of the channel too deep in the first pass... twas kinda rough.... wound up routing everything to that level and then thicknessing the top so the channel was the proper depth... pissed me off something fierce... but I made it thru it.

the jig required that the first pass be super heavy and I think the vibration was what knocked the bit loose... either way, next time i'll build a completely different jig so it's not a problem.....

^ EXACT same thing happened to me a while back, however I didnt have enough stock to shave it down like that. I wound up splitting the neck down the middle and gluing in a laminate to build back the material of the truss rod slot and re-cut it with a circular saw first, and finished it with the router.

thanks for the kind words guy's.

No build ever goes as smoothly as you hope it will.

Im using new tools with new tecniques (for me)

Im actually surprised there hasnt been more carnage yet...

Next one will be flawless right?? hahaha... yeah... not likely...

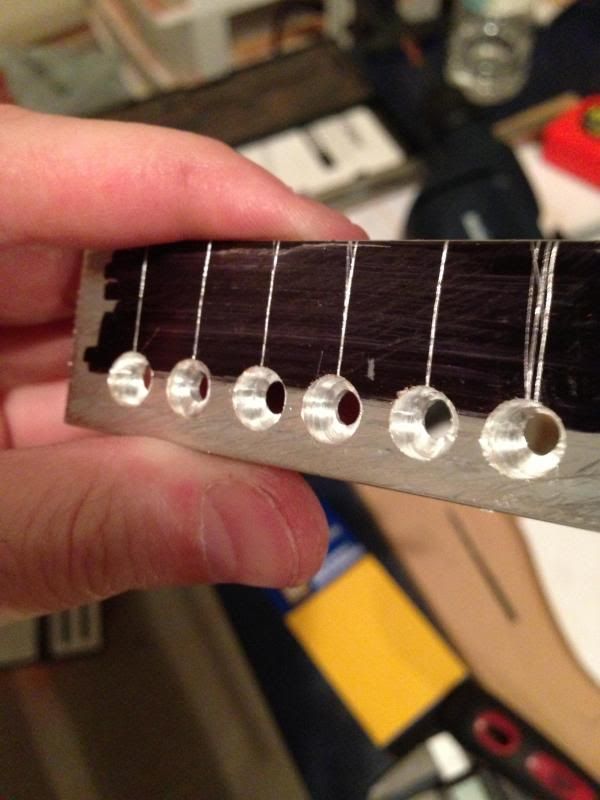

To avoid these kind of scratch, you can put under you head stock another piece of wood. It's the lack of material that cause your problem. Your drill push the wood fibers and if there's nothing under it cracks !!

To avoid these kind of scratch, you can put under you head stock another piece of wood. It's the lack of material that cause your problem. Your drill push the wood fibers and if there's nothing under it cracks !!

Hope your repair is good! Nice choice of wood, specially for the neck. You xill have really nice maple parabola when it will be shaped !

the scrap wood would not have helped on this one anyways due to the way the damage was created.

the scrap wood would not have helped on this one anyways due to the way the damage was created.AH ok! sorry dude, I didn't catch itHeya Youne,

My intent was not to drill all the way through. I was trying to create a stepped diameter hole so the tuners would fit nice