Manton Customs

Well-Known Member

It's been too long since I shared anything due to general busyness and lack of time...so lets put that right! Here is one of the projects I have been working on during the short social media/forum hiatus. It's an 8 string True Temperament guitar built in the style of a Cello, featuring a Spruce top, F holes and Ebony fingerboard, see the specs below for a full list. The philosophy behind this being the meeting of two worlds- traditional (Cello) and modern (see spec!).

This commission is now complete and the guitar is already with it's new owner (whom shall be revealed later) so the updates will be going up quicker than usual and pictures of the finished guitar just around the corner.

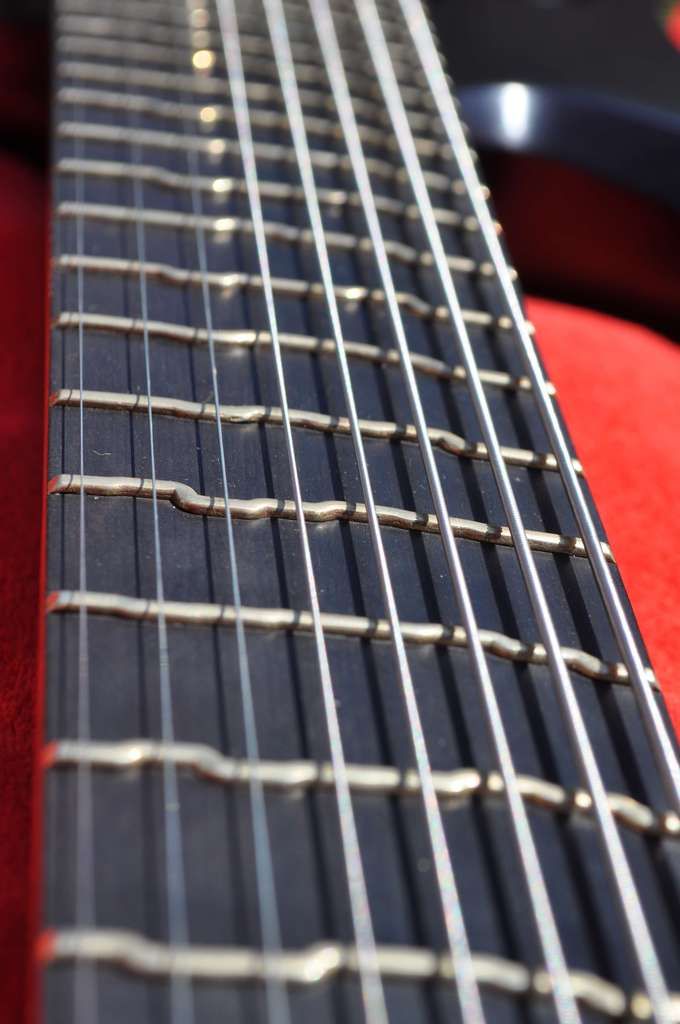

Perhaps the most interesting thing about this guitar is the True Temperament system. For this guitar the neck was sent off to Sweden where it was fretted by TT. We are very impressed by the system and it really does have a noticeable effect on the guitar. Every note is perfectly in tune. This was the first TT guitar we have done but will not be the last, with a second one already in process.

8 String

27" scale

True Temperament

Bolt On

Mahogany Body

Thick Carved Spruce top

5 Pc Maple and Black Walnut Neck

Matching Spruce Head Plate

AAA Grade Ebony Fingerboard

Large Inlay Spanning Lower Frets

F Holes

Chambered

Floyd Rose Bridge

Seymour Duncan Black Winter Pickup Set

CTS Pots

Gotoh 510 Tuners

Schaller Strap Locks

This was our starting point. A rough picture the client generated. We made some noticeable changes to the actual guitar. Most importantly the headstock which was changed to a 4+4 tuner layout. The F holes were also moved to a more appropriate location and the control layout revised to incorporate a tone control. The inlay here is also different.

Here are the neck woods which have been planed and are ready to be glued up

And here they are in the clamps! In answer to what you are thinking...No I do not glue up outside! The blank was carried out to benefit from better lighting for the picture

Here it is after it has been through the planer

Another neck blank shot.

Onto the body! This is the body template, notice the two cutouts either side, these are for the chambers which will be under the F holes. Careful thought was given to the location of these chambers as it would have been disastrous to place them somewhere which was going to be carved into or have hardware mounted to (pickups, bridge etc) and space was tight! They also needed to be in a location where the F holes looked correct and pleasing to the eye.

The Mahogany body being glued up. Notice the large pine cauls at the top and bottom, these keep the two halves level during glue up.

This is the body after it has come out of the clamps and is being lightly planed by hand to ensure 100% flatness for it to later receive the Spruce top.

That's all for now, stay tuned for more updates very soon!

Next up we cut the angle for the headstock, I use a bandsaw to rough cut followed by a handplane to smooth it out. This guitar will have a volute to reinforce the headstock without using a scarf joint.

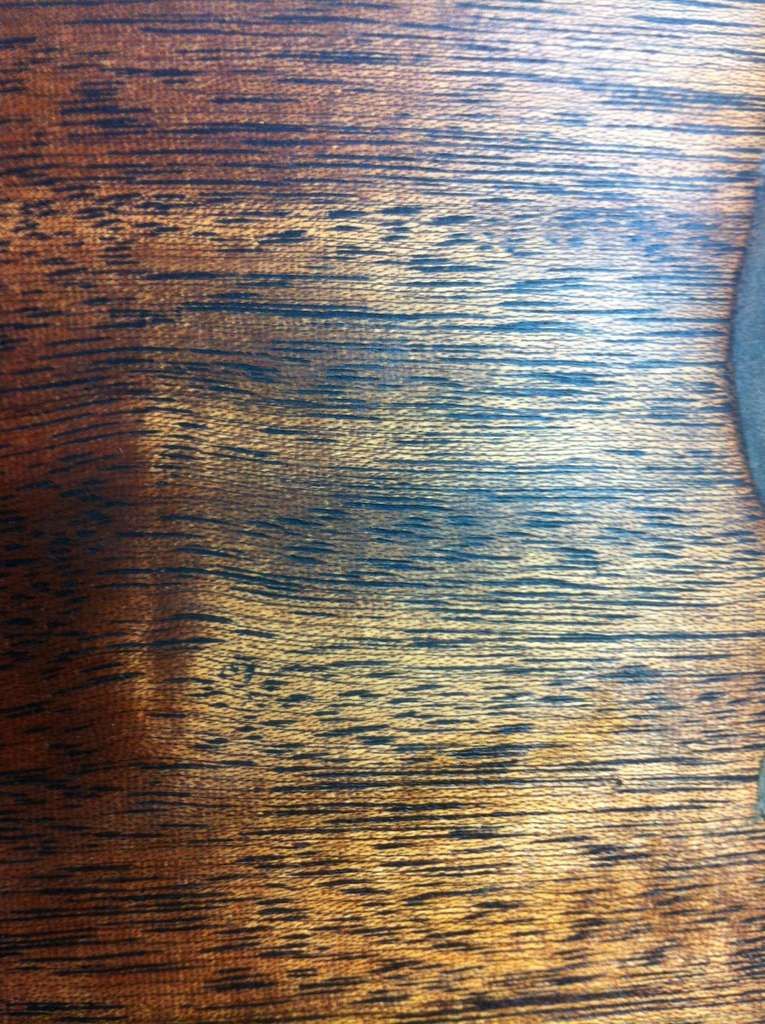

Here's a shot of the now planed headstock angle and a good close up of the neck laminates.

Next I rout for the double action truss rod using this very simple jig.

The truss rod in place and the jig still attached to the neck

Now I saw away the waste (which will be used for another neck blank) from the back and plane the neck down to the final thickness of the heel.

Here is the very rough profile sawn out and viewed from the side. Notice the lump behind the headstock... this will form the volute.

The templates attached, ready to be cut out using bandsaw and router.

More updates coming soon!

This commission is now complete and the guitar is already with it's new owner (whom shall be revealed later) so the updates will be going up quicker than usual and pictures of the finished guitar just around the corner.

Perhaps the most interesting thing about this guitar is the True Temperament system. For this guitar the neck was sent off to Sweden where it was fretted by TT. We are very impressed by the system and it really does have a noticeable effect on the guitar. Every note is perfectly in tune. This was the first TT guitar we have done but will not be the last, with a second one already in process.

8 String

27" scale

True Temperament

Bolt On

Mahogany Body

Thick Carved Spruce top

5 Pc Maple and Black Walnut Neck

Matching Spruce Head Plate

AAA Grade Ebony Fingerboard

Large Inlay Spanning Lower Frets

F Holes

Chambered

Floyd Rose Bridge

Seymour Duncan Black Winter Pickup Set

CTS Pots

Gotoh 510 Tuners

Schaller Strap Locks

This was our starting point. A rough picture the client generated. We made some noticeable changes to the actual guitar. Most importantly the headstock which was changed to a 4+4 tuner layout. The F holes were also moved to a more appropriate location and the control layout revised to incorporate a tone control. The inlay here is also different.

Here are the neck woods which have been planed and are ready to be glued up

And here they are in the clamps! In answer to what you are thinking...No I do not glue up outside! The blank was carried out to benefit from better lighting for the picture

Here it is after it has been through the planer

Another neck blank shot.

Onto the body! This is the body template, notice the two cutouts either side, these are for the chambers which will be under the F holes. Careful thought was given to the location of these chambers as it would have been disastrous to place them somewhere which was going to be carved into or have hardware mounted to (pickups, bridge etc) and space was tight! They also needed to be in a location where the F holes looked correct and pleasing to the eye.

The Mahogany body being glued up. Notice the large pine cauls at the top and bottom, these keep the two halves level during glue up.

This is the body after it has come out of the clamps and is being lightly planed by hand to ensure 100% flatness for it to later receive the Spruce top.

That's all for now, stay tuned for more updates very soon!

Next up we cut the angle for the headstock, I use a bandsaw to rough cut followed by a handplane to smooth it out. This guitar will have a volute to reinforce the headstock without using a scarf joint.

Here's a shot of the now planed headstock angle and a good close up of the neck laminates.

Next I rout for the double action truss rod using this very simple jig.

The truss rod in place and the jig still attached to the neck

Now I saw away the waste (which will be used for another neck blank) from the back and plane the neck down to the final thickness of the heel.

Here is the very rough profile sawn out and viewed from the side. Notice the lump behind the headstock... this will form the volute.

The templates attached, ready to be cut out using bandsaw and router.

More updates coming soon!