Erik Hauri

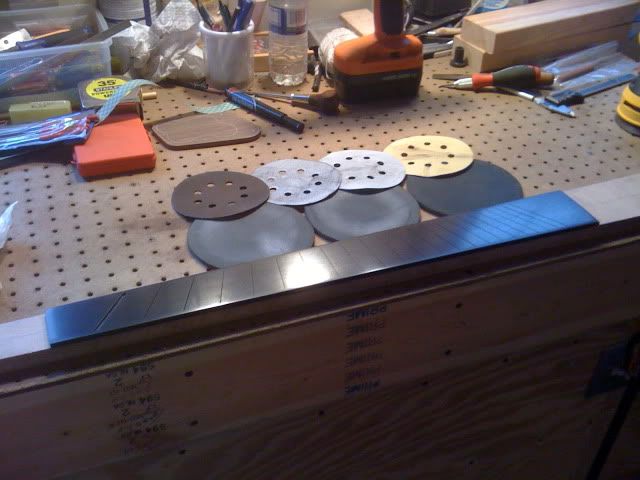

Lumber -> Guitars

The brass ball-end retainer plate, with ground wire soldered on, is inlayed into the back and now it's time to glue the back plate on.

For this I'm using - again - the West System epoxy adhesive. No special reason except that I like it, it has more "open time" on it than Titebond, and I'm relaxed and not in a rush today. Titebond would have been fine too.

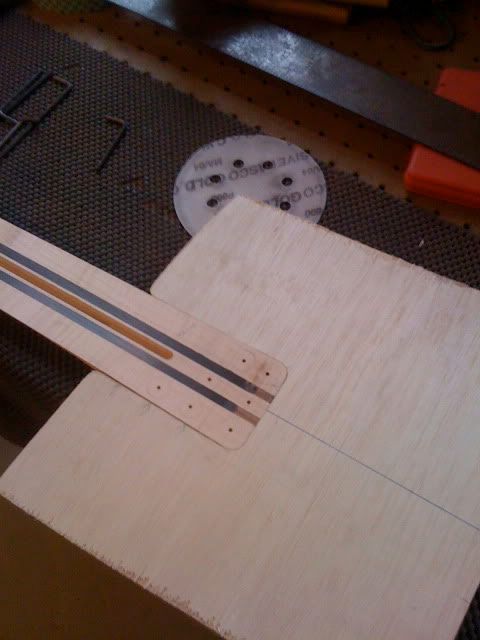

In this shot notice that I've drilled the string-through holes through the back - I have an outline drawn that will allow me to line them up perfectly with the bridge plate inlayed into the body core once the two are laid up together.

The back goes into the press on a layer of wax paper.

Then the body core goes over top, being VERY careful to keep it well aligned as I tighten the press screw onto a black limba block to distribute the pressure. I don't need a ton of pressure here, just enough to close the joint and make sure I have squeeze-out all around the body. The green wire is the ground wire from the ball-end retainer.

Sorry for the blurry shots today - wearing rubber gloves and trying not to get epoxy on the iPhone....

The left-over epoxy is used to stabilize a couple of knots on the top, which will mostly be routed away for the pickups anyway, but still...

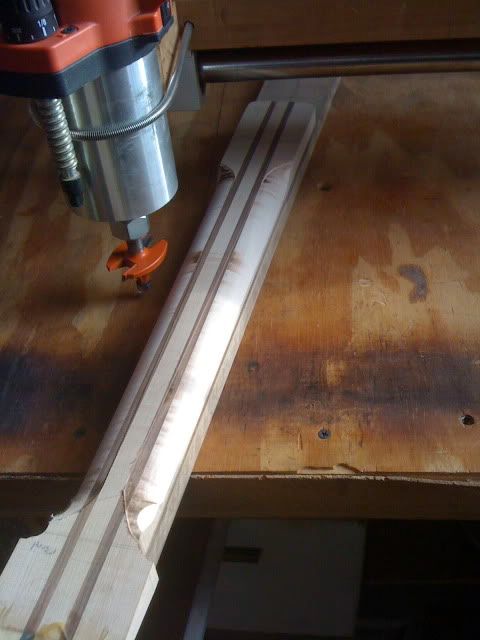

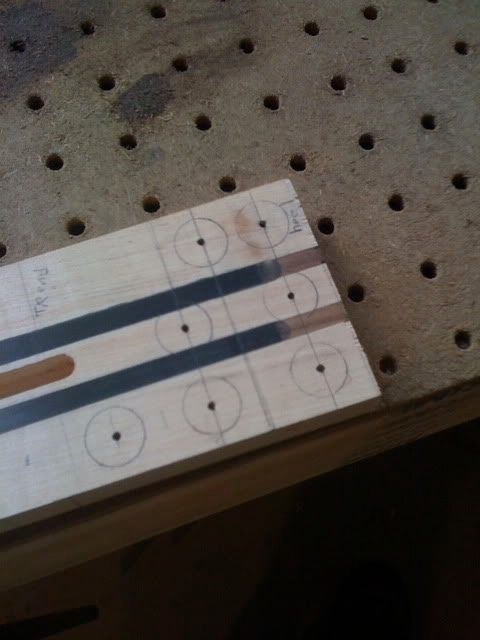

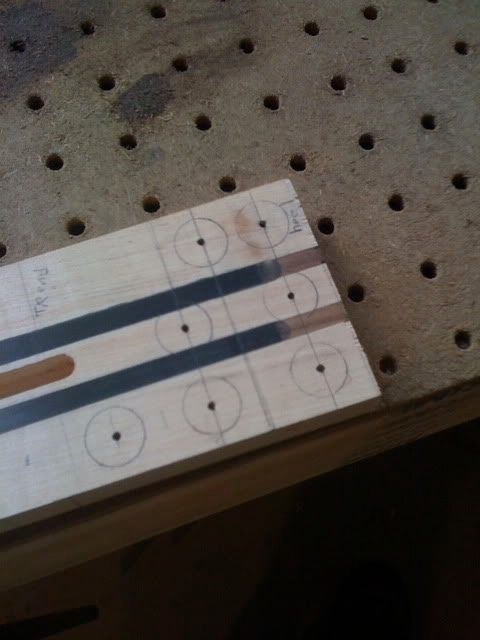

And now laying out the screw holes in the neck heel - want to avoid drilling into the CF bars! Pilot holes will be drilled here on the drill press, and once the neck pocket is routed, these will serve as guides as I drill through the bottom of the neck pocket. Perfect hole alignment will be the result.

There is an extra screw on the bass side as there will be more string tension there, and the treble-side holes are closer together because the heel underneath the neck pocket will be sculpted to improve upper-fret access.

For this I'm using - again - the West System epoxy adhesive. No special reason except that I like it, it has more "open time" on it than Titebond, and I'm relaxed and not in a rush today. Titebond would have been fine too.

In this shot notice that I've drilled the string-through holes through the back - I have an outline drawn that will allow me to line them up perfectly with the bridge plate inlayed into the body core once the two are laid up together.

The back goes into the press on a layer of wax paper.

Then the body core goes over top, being VERY careful to keep it well aligned as I tighten the press screw onto a black limba block to distribute the pressure. I don't need a ton of pressure here, just enough to close the joint and make sure I have squeeze-out all around the body. The green wire is the ground wire from the ball-end retainer.

Sorry for the blurry shots today - wearing rubber gloves and trying not to get epoxy on the iPhone....

The left-over epoxy is used to stabilize a couple of knots on the top, which will mostly be routed away for the pickups anyway, but still...

And now laying out the screw holes in the neck heel - want to avoid drilling into the CF bars! Pilot holes will be drilled here on the drill press, and once the neck pocket is routed, these will serve as guides as I drill through the bottom of the neck pocket. Perfect hole alignment will be the result.

There is an extra screw on the bass side as there will be more string tension there, and the treble-side holes are closer together because the heel underneath the neck pocket will be sculpted to improve upper-fret access.

can't wait to see more

can't wait to see more