aaron_rose

more bigger

the only instal video i can find is for a acoustic...

This site may earn a commission from merchant links like Ebay, Amazon, and others.

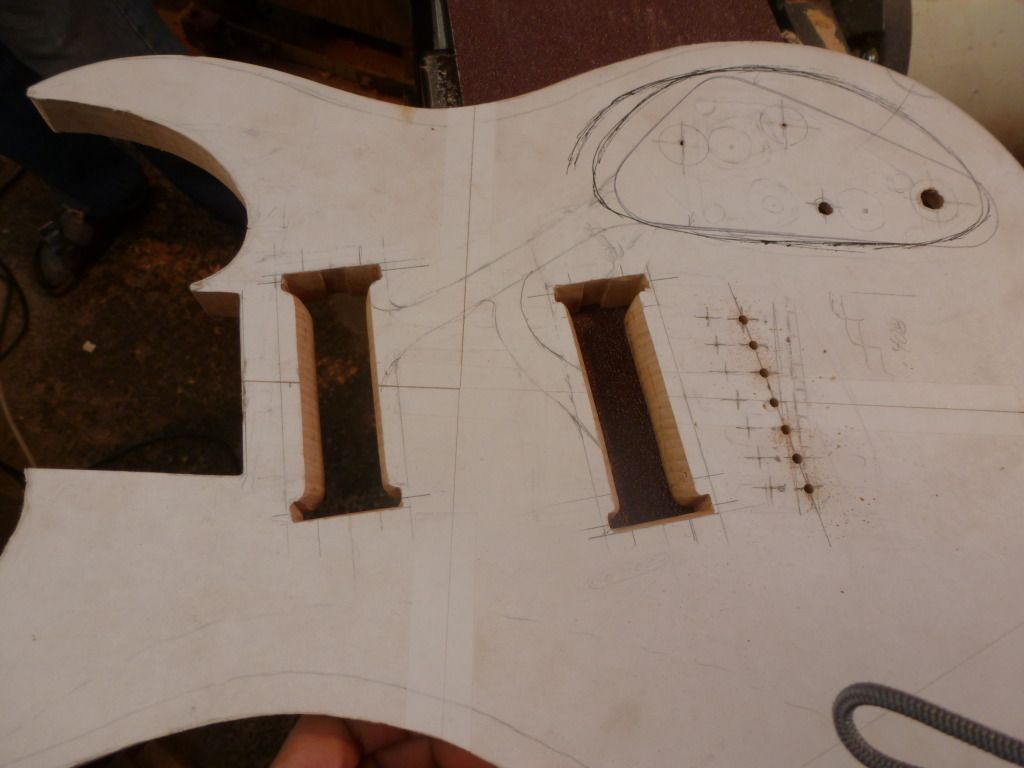

Definitely go the way of the routerYou can make as many mistakes as you need to cutting a proper-fitting template out of MDF or decent-quality plywood, then once it looks and fits right, double-stick foam tape it in position and route the cavities to the required depth with a flush-trim ball-bearing guide router bit. The bit should only cost about $15-$20 and will save you HOURS in the long run, especially because the template is reusable.

So much this.

Just a couple of things. Do NOT use foam double tape. Since it's foam, your template WILL move around as you press agaist it. There are tons and tons of kinds of double sided tape, just look for one without foam, should have no problem finding it.

As for the router bit, a good 2" bit with ballbearings should cost around $40, but holy hell, are they worth it. Or you can buy a smaller bit, and route the shape by layers... pretty much like a CNC would.

Btw, check these guys out. I'm in love with their router bits. They may have horrible customer service, but they sure know how to make the best router bits... and they are cheap!

MLCS Router Bits and Woodworking Products

edit: check out the katana bits =D

So much this.

Just a couple of things. Do NOT use foam double tape. Since it's foam, your template WILL move around as you press agaist it. There are tons and tons of kinds of double sided tape, just look for one without foam, should have no problem finding it.

As for the router bit, a good 2" bit with ballbearings should cost around $40, but holy hell, are they worth it. Or you can buy a smaller bit, and route the shape by layers... pretty much like a CNC would.

Btw, check these guys out. I'm in love with their router bits. They may have horrible customer service, but they sure know how to make the best router bits... and they are cheap!

MLCS Router Bits and Woodworking Products

edit: check out the katana bits =D

So much this.

Just a couple of things. Do NOT use foam double tape. Since it's foam, your template WILL move around as you press agaist it. There are tons and tons of kinds of double sided tape, just look for one without foam, should have no problem finding it.

As for the router bit, a good 2" bit with ballbearings should cost around $40, but holy hell, are they worth it. Or you can buy a smaller bit, and route the shape by layers... pretty much like a CNC would.

Btw, check these guys out. I'm in love with their router bits. They may have horrible customer service, but they sure know how to make the best router bits... and they are cheap!

MLCS Router Bits and Woodworking Products

edit: check out the katana bits =D