jwade

Doooooooooom

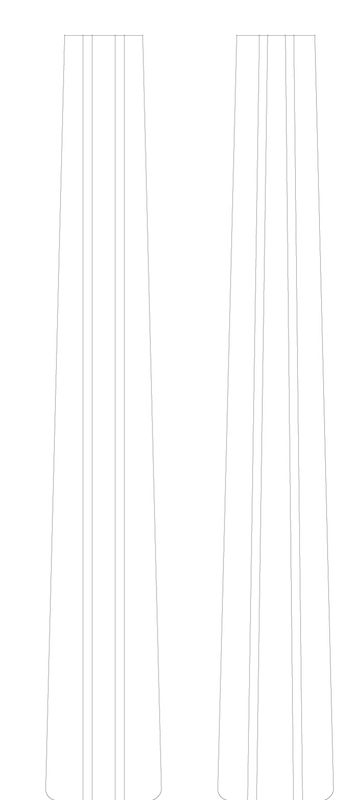

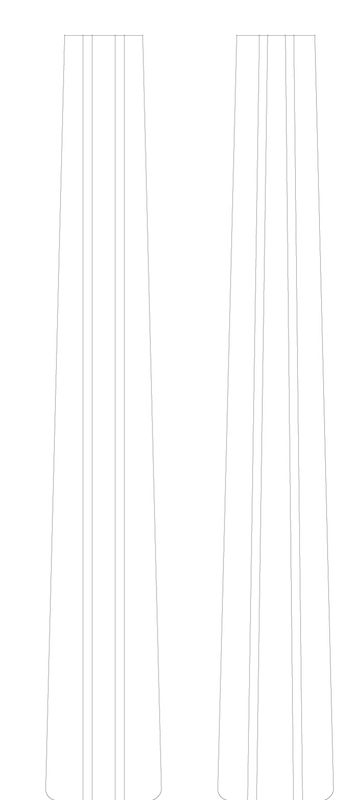

I've been wondering about neck laminates. For example, on a 5 piece neck, say maple/wenge/maple/wenge/maple. Are there any benefits or drawbacks to having the thinner laminates run parallel to each other, or would it work to do a center laminate that flares out to have the two thinner piece match the gradual widening of the neck at the heel?

In case I've worded the question stupidly (as I've just woken up), here's a quick illustrator mockup to attempt to show what I'm asking about:

In case I've worded the question stupidly (as I've just woken up), here's a quick illustrator mockup to attempt to show what I'm asking about: